Ernest Wright

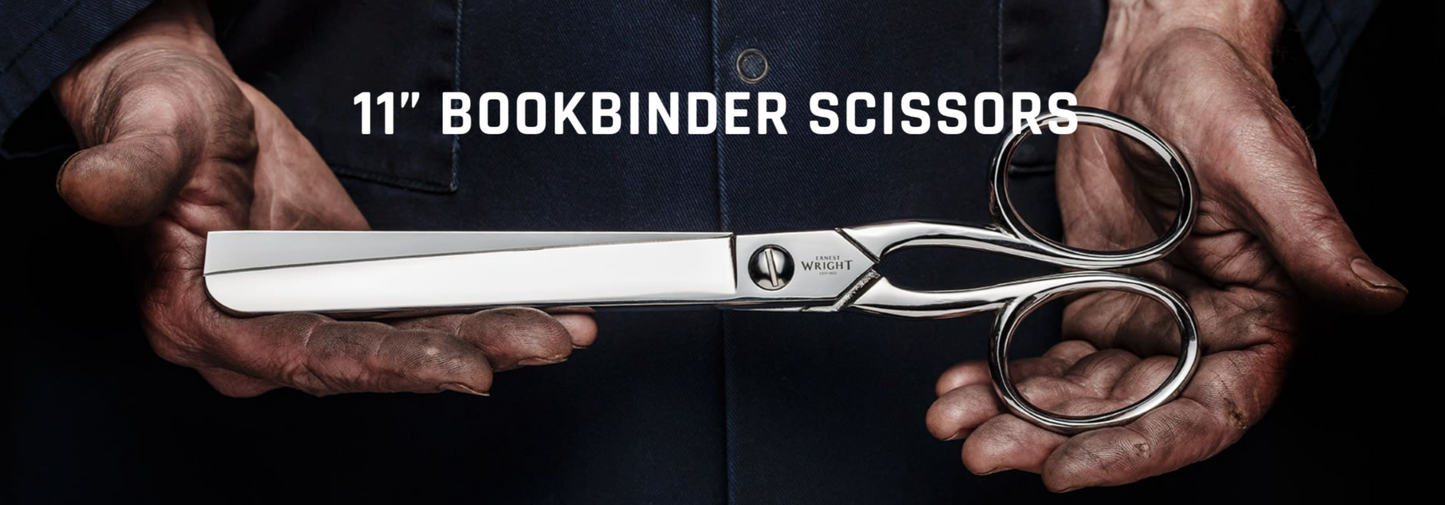

Ernest Wright Bookbinder 11 inch Scissors

Ernest Wright Bookbinder 11 inch Scissors

Couldn't load pickup availability

The world's finest scissors handmade in Sheffield, aka "Steel City".

A bookbinder works with paper, bookcloth and sometimes leather to mend or create cherished books. Perfecting each component requires a cutting technique that is at once crisp, decisive and careful.

The 11″ Bookbinder Scissors are designed to meet the particular requirements of the bookbinder’s craft. The blades are long, straight, and enduringly sharp thanks to their carbon steel composition. Crucially, their cutting length exceeds the height and width of most books – so they can cut the materials in one or two actions.

Whereas some craftspeople, such as embroiderers and quilters, require scissors with a sharp point, in bookbinding a pointy tip brings the risk of removing slightly too much material. To help bookbinders cut with perfect accuracy – especially around the tricky corners of bookcloth and paper pieces – a flat, soft-edged point has been ground onto the 11″ Bookbinder Scissors.

The 11″ Bookbinder Scissors have been adapted from a 1980s pattern of Paperhanger Scissors, which is also part of the Ernest Wright range. While the Bookbinder Scissors were custom-made for bookbinding, they are also suitable for some other crafts where precision is paramount, such as collage-making.

Learn how Ernest Wright scissors are made:

- from ITV4: https://www.youtube.com/watch?v=qEzyHN6q5kY

- from Business Insider: https://www.youtube.com/watch?v=bK4AWtTV3h4

- Sheffield Museums: https://www.youtube.com/watch?v=9Hf9GfrOyRI

Why it's special:

- Hot drop forged high quality carbon steel for long-life precision edge retention

- Hand polished finish

- Handmade brown leather pouch included

- Lifetime warranty

Specs:

- Carbon steel

- Total length: 11" / 29.94 cm

- Blade length: 5.7" / 14.48 cm

- Handmade in Sheffield England

Care of carbon steel scissors:

- After use, always wipe your carbon-steel scissors clean and dry, and store them away from any water, salt or humidity. It is preferable to store these wrapped (or encased) in dry cloth, dry leather, or a dry cardboard box, to protect them from airborne moisture.

-

To properly wipe any scissors and shears clean and dry: Use clean, soft, dry absorbent material (we use microfibre cloths for example). With the scissors *wide* open, try wiping ALL the insides you can get into, especially close to the insides of the screw area. Pay as much attention as possible to the insides of the backs, and the insides of the blades, on both sides of the pair. Then work the scissors a few times, and perform the same wipe again.

-

Buff the outsides of the closed scissors with the same (possibly now oily) piece of cloth, and finally give them a really good clean dry wipe all over with a clean dry piece (or area) of cloth.

-

Occasionally you may try a proportionally small drop of household or machine oil, aimed to get deep inside the screw area between the two halves of the scissors. Work the oil in really well by opening and closing them many times. A couple of drops / attempts may sometimes help. Then repeat a very good wipe again, as explained above.

-

Watch out for any tiny oil leakage from the screw with your first few cuts… especially before you start on anything precious! Any oil seepage will not last, but it is important to watch out for at first!

-

Never let anyone ‘play about’ with or ‘adjust’ the screw – ever! It is fixed in place for a reason; moving it could even eventually cause your scissors to fall apart.

Share